While I’m still loving my PrintrBot Simple Metal I fell out of love with the noise it made while it shared my desk. I now have my 3D printer in a far corner but still accessible from the network – it is a huge help for my sanity. I can monitor my prints but don’t have to listen to the printer bump along throughout the day. To make this happen I used three pieces of software. Sketch-up, Cura, and Octoprint.

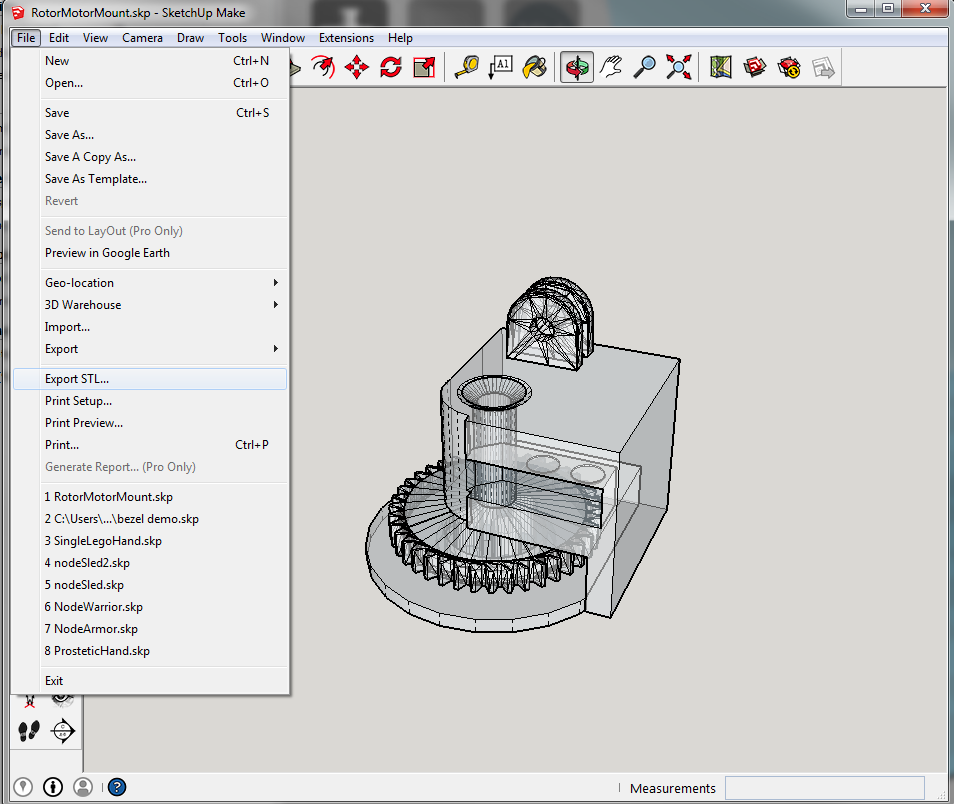

Sketch-up

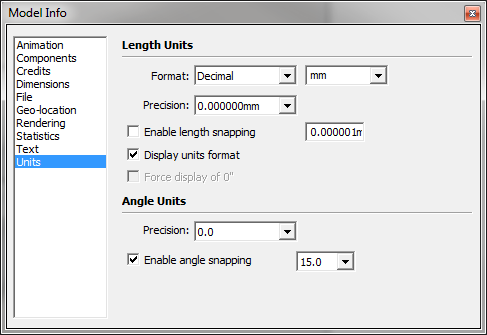

If you are familiar with CAD software this is an easy one to pick up. You can create some interesting, complicated objects to print, but you need to follow a few steps first.

- Under Window on the toolbar select model info and make sure to set the format to Decimal and MM

- At least on my machine, the slicing software will sometimes ignore lines/forms that are narrower than the nozzle. For structural measures I take this a little further and try not to make anything less than 1 mm in any direction. The exception to this is if I am making a rabbit on the edge of an object. That tends to work out well.

You will need to download an extension to export out the stl files. Once you have the export file you can open it in CURA.

I like “SketchUp STL by SketchUp Team Import and Export STL files for 3D printing” but there are several in the extensions warehouse to choose from.

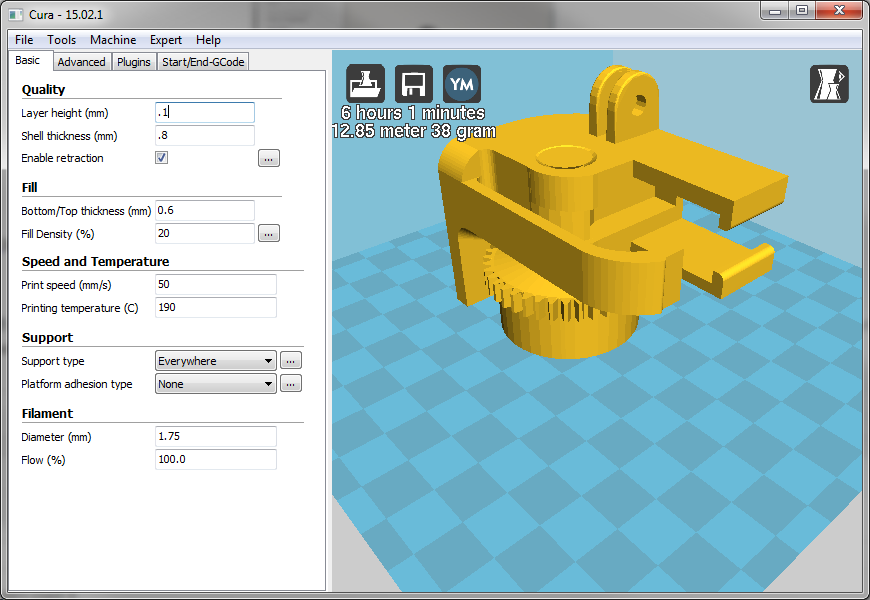

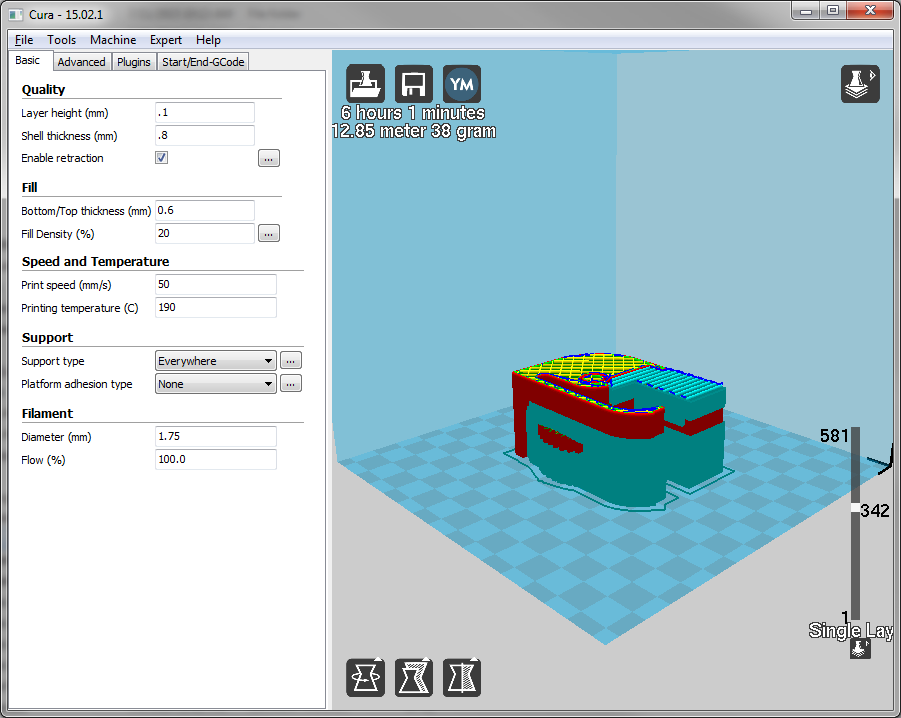

Cura by Ultimaker

Cura is nice slicing software. I started off using Cura to print directly to my Printrbot, and now use it to create the gcode files I upload to Octoprint. You can set up the software for your particular printer from a template or make your own custom printer layout. Once you have your stl file, you can simply drag and drop it into cura.

Based on your settings, Cura will render the object, show you where you can have problems due to the model, and let you save it out to a gcode file. The following image shows the slicing that Cura generates for this particular model.

Once you are happy with the results, save the object using the disk icon at the top, and upload it to OctoPrint.

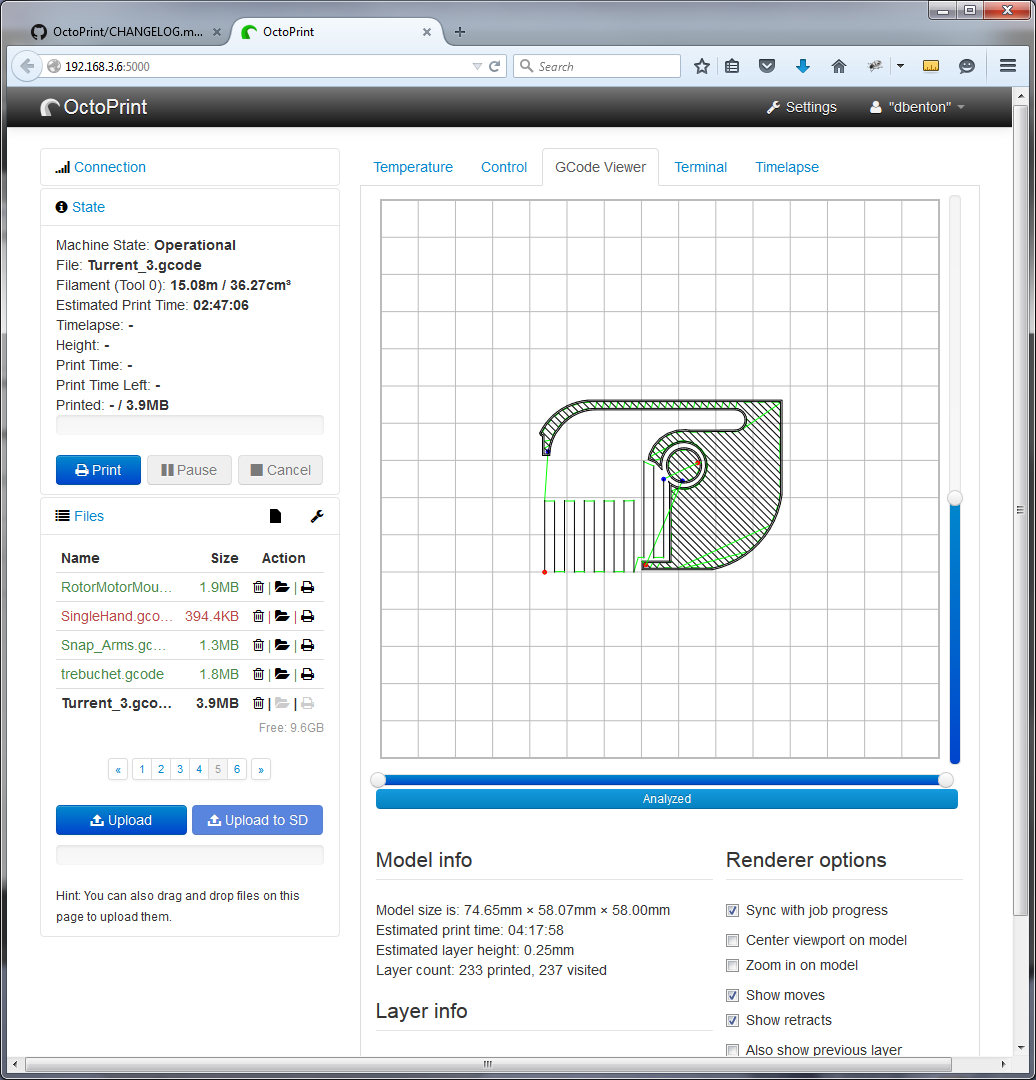

OctoPrint

OctoPrint is a browser interfaced printer server for 3D printers. Scott Hanselman did a podcast with the author of octoprint back in April. If you get a little time you really should listen to it.

Anyway, I use octoprint to make my printer available to all my home users. I host it on a Raspberry Pi 2, and use it to monitor my prints from anywhere my WIFI reaches. I use the gcode viewer for every print to make sure I do not have any voids that would leave the object structurally unsound. I also appreciate the ability hook up a camera and see the print in real time without the need to run up and down the steps to monitor the print job.

This is just one way you can create and print your 3D designs. There are many many others. Please feel free to comment and describe your own methods for getting your models from concept to reality.